Environmental Zhangjiagang High Quality Plastic Film Shredder Machine

Overview Package size per unit product 500.00cm * 200.00cm * 200.00cm Gross weight per unit product 2700.000kg Environme

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | XS Series |

| Raw Material | Post-Consumer/Post Industry/in-House Plastic Waste |

| Structure | Top Feed |

| Knife Classification | DC53 |

| Knife Roll | Solid Knife Roller |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| Voltage | 380V 50Hz or Customized |

| Electric Components | ABB, Ls, Omron, or Customized |

| Application | Waste Plastic |

| Capacity Range | 200-6000kg/H |

| After-Sale Service | Free Spare Parts |

| OEM | Available |

| MOQ | 1PC |

| Supply Type | Customzied |

| Control | P.L.C Control |

| Advantage | Famous Brand Motor |

| Business Type | Manufacturer |

| Sample/Service Manual | Available |

| Factory Location | 2 Hours Drive From Shanghai |

| Material | Iron |

| Transport Package | Wooden Pallet |

| Specification | Customzied |

| Trademark | ACERETECH |

| Origin | Zhangjiagang City, Jiangsu, China |

| HS Code | 8477800000 |

| Production Capacity | 100 |

Packaging & Delivery

Package size per unit product 500.00cm * 200.00cm * 200.00cm Gross weight per unit product 2700.000kgProduct Description

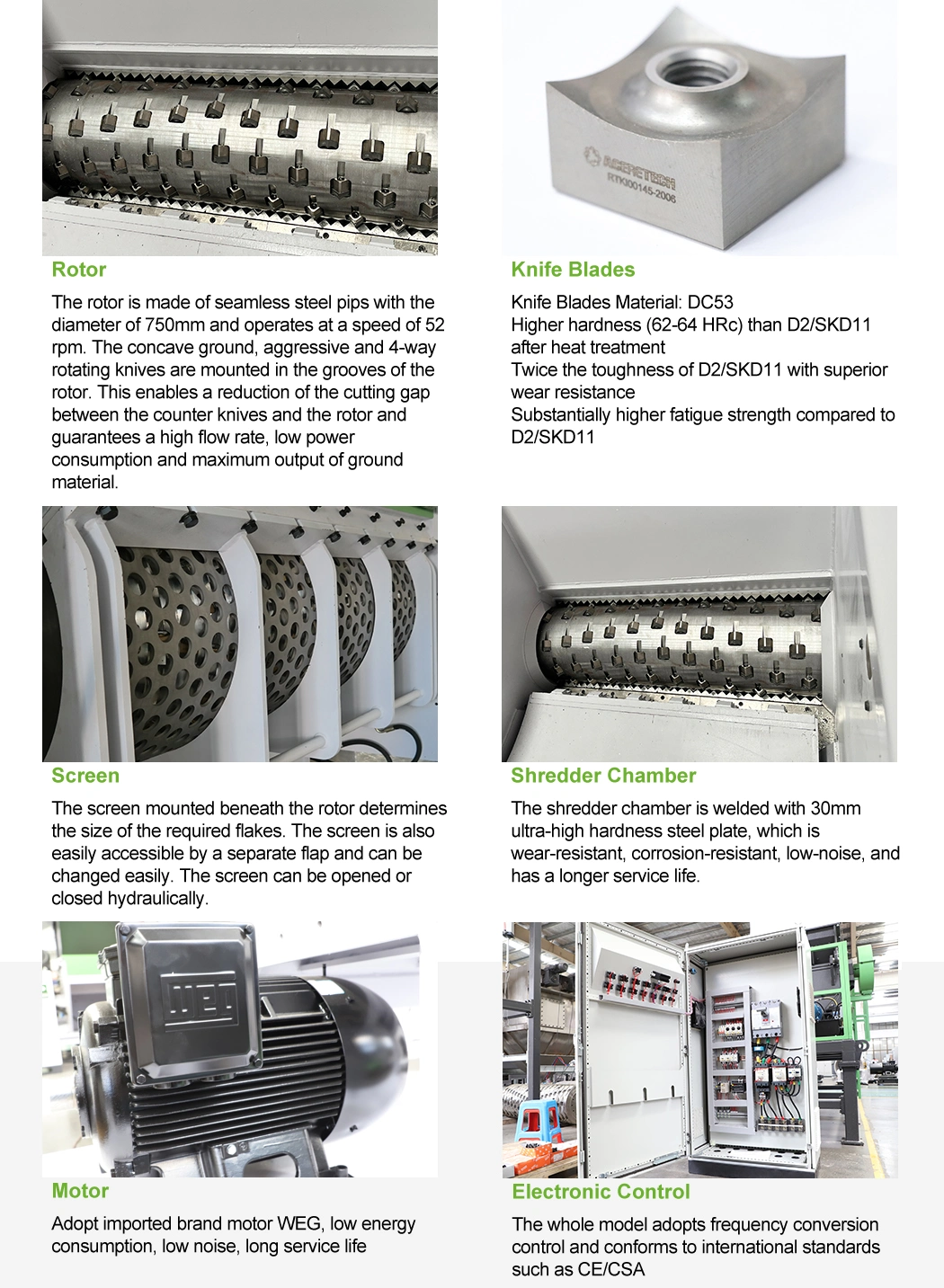

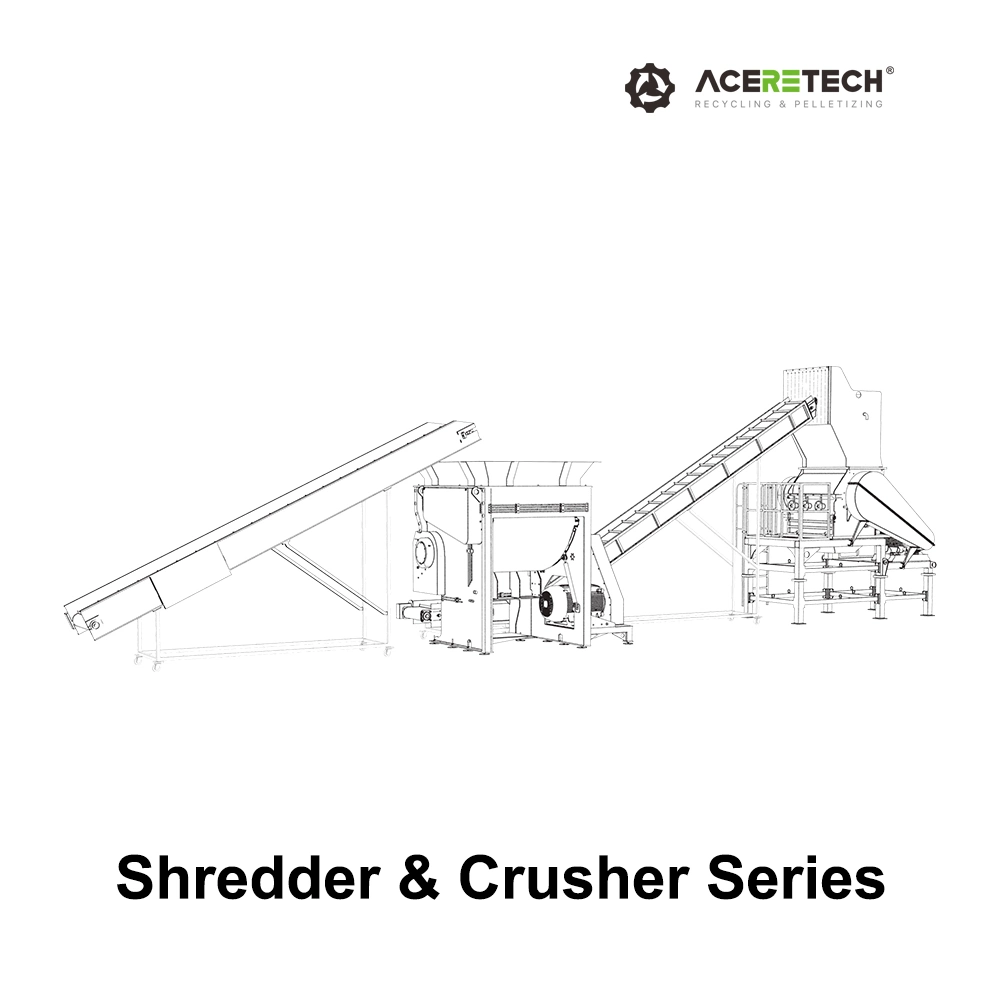

Environmental Zhangjiagang High Quality Plastic Film Shredder MachineProduct DescriptionXS series shredder is a heavy-duty single-shaft shredder equipped with a powerful two-speed swing-type hydraulic pusher. This design can avoid the occurrence of material blocking and reduce the wear of the internal guide rail. This model is welded by a special welding process. The mechanical structure is stronger. The crushing capacity of the single machine is 30-40% higher than that of other brands. It is suitable for recycling various waste materials. The shredder is equipped with diameter 750mm ACERETECH effective V type rotor with width ranging from 1500mm to 3000m. The low speed of 45rpm ensures smooth running with high torque.The hydraulic workstation is tightly integrated with the shredder chamber, which saves space and protects the hydraulic station,and is easy to replace and maintain. XS series heavy-duty single-shaft shredder adopts intelligent PLC control system. The rotor can be surface hardened and wear-resistant according to customer requirements. According to the characteristics of different shredded materials, we provide customers with optional water cooling systems.Application:XS series heavy-duty single-shaft shredders can meet customers' requirements for high-capacity shredding. They are widely used in wide or thick waste cardboard, refrigerator shells, large household appliance shells, daily life waste products, rubber products and automobile tires.

Product Parameters| Item | Unit | XS1500 | XSX2000 | XS3000 |

| Feed opening | mm | 2540x1620 | 2540x2020 | 2540x2820 |

| Rotor diameter | mm | 750 | 750 | 750 |

| Rotor speed | rpm | 52 | 52 | 52 |

| Motor power | kw | 2x75 | 2x90 | 2x132 |

| Number of rotor knives | pcs | 76 | 96 | 136 |

| Number of stator knives | pcs | 4 | 5 | 7 |

| Motor of hydraulic device | kw | 11 | 11 | 11 |

| Screen size | ton | 40~100 | 40~100 | 40~100 |

| Chamber size | mm | 1500x1490 | 1500x1900 | 1500x2700 |

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME

* ACERETECH is original manufacturer.

* If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.

* The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.