TF900 CNC Saw Blade Sharpening Machine for Metal Cold Cutting Saw Blade Grinding

Package size per unit product 250.00cm * 180.00cm * 220.00cm Gross weight per unit product 3680.000kg 6-Axes CNC Control

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | TF900 |

| Processing Object | Top/Face/Notch/Groove of Sawblade |

| Abrasives | Grinding Wheel |

| Controlling Mode | CNC |

| Automatic Grade | Automatic |

| Cylindrical Grinder Type | Plunge Cylindrical Grinder |

| Precision | High Precision |

| Certification | CE, ISO 9001 |

| Condition | New |

| Saw Blade Dia | 120~810mm |

| Hook Angle | 25°~ -30° |

| Top Angle | 8°~ 30° |

| Top Chamfer Angle | 45°~ -45° |

| Bore Diameter | 12~120mm |

| Wheel Speed | 2500~3500rpm |

| Grinding Speed | 6~30s/Tip |

| Power | 5kw |

| Weight | 3680kg |

| Voltage | AC 380V-50Hz/220V-60Hz |

| Item | Tct Saw Blade Sharpening |

| Function | Top/Face/Notch/Groove Grinding |

| Application | Carbide Tips Sawblade Sharpening |

| Application2 | Cold Saw Blade Sharpening Machine |

| Application3 | Sawmill |

| Transport Package | Water Proof + Wood Carton |

| Specification | 2500*1800*2200mm |

| Trademark | TORSEL |

| Origin | China |

| HS Code | 8460310000 |

| Production Capacity | 5000units/Year |

Packaging & Delivery

Package size per unit product 250.00cm * 180.00cm * 220.00cm Gross weight per unit product 3680.000kgProduct Description

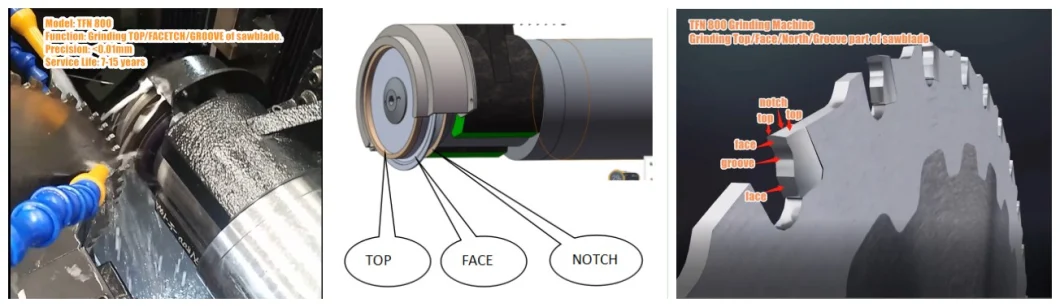

6-Axes CNC Controlled Saw Blade Grinding Machine for cermet tips saw blade manufacturingIntroduction: This is the most advanced cermet tips grinder machine. 6-axes servo controlled,fully automatic grinding for cermet tips top,face,chamfer,groove and chip breaker. Complete angles grinding is finished in one set up, the processing efficiency is 20-50mins/tip,productivity & efficiency is sharply improved. Precision is controlled in 0.02mm. Be widely to used for cermet tips saw blade manufacturing.

High-level productivity & precision grinding machine for carbide tools.• Saw Dia: <800mm

• Function: Tooth Top/Face/Notch/Chip Break Slot/negtive chamfer angle sharpening• Precision: <0.02mm

• Model: TNF 800

• High precision, more function & more productivity, PURCHASE is cost-effective.• Cooperation Company

Advantages of sawblade grinding machine

• More precision- grinding precision: <0.002mm,be impressed by the higher accuracy.

• More efficiency- experienced productivity on a higher level

• More user comfort- simplify your work

• More flexibility-for precision in any requirement

• More Function- grinding TOP/FACE/NOTCH/GROOVE/negative chamfer angle of sawblade

Presetting for tooth TOP/FACE/NOTCH grinding

CNC Control- High Precision is flexible to control ultra-precision grinding as requirement.

3-D Graphics Grinding Machine

Technical Premeter

| Saw Blade Diameter | 120~810mm |

| Hook Angle | 25°~-30° |

| Top Angle | 8°~ 30° |

| Top Chamfer Angle | 45°~ -45° |

| Face Chamfer Angle | 30°~ -30° |

| Bore Diameter | 12~120mm |

| Pitch | 2~80mm |

| Top wheel size | Φ125mm*Φ32mm*16mm |

| Notch wheel size | Φ125mm*Φ32mm*9mm |

| Face wheel size | Φ150mm*Φ32mm*14mm |

| Wheel Speed | 2500~3500RPM |

| Grinding Speed | 6-30s/tip |

| Power | 5KW |

| Dimensions | 2500*1800*2200mm |

| Weight | 3680kg |

Configuration

| Ball Screw | THK (JAPAN) |

| Crossed Roller Guide | THK (JAPAN) |

| Pneumatic Parts | SMC(Japan) |

| Servo Motor | Inovance |

| PLC | Inovance ARM600 |

| Harmonic Drive | Inovance |

Please contact with me for more information:

FAQ

1. How to chooce best saw blade grinding machine?

- Best grinding machine process tools with higher precision & long service life.

2. How is the performance of TORSEL saw blade grinding machine?

- TORSEL saw blade grinding machine process tool with excellent precision <0.01mm,the service life is upto 7-15 years.

3. Whats your cooperation companys?

4. How to do if I can not operate?If you have operation problem when you get the sharpeners, we will make video meeting to teach you. If video teaching can not solve, our engineers will go to your place, and all charges paid by customer's side.

5. How to get spare part after warrantyOne of our sharpeners is working for Korea Resharpening service for 15 years,we still serve with after sale service.If buyers need spare parts,or there is any problems after waranty, we will always responsible for TORSEL sharpeners, including find problems, send spart parts, and teach you to replace the parts. .

Related Products

-

![Best Price Waste Air Conditioner AC Radiator Separator Aluminium Copper Radiator Scrap Recycle Machine]()

Best Price Waste Air Conditioner AC Radiator Separator Aluminium Copper Radiator Scrap Recycle Machine

-

![Popular Motor Winding Machine Bf Scrap Electric Motor Recycling Copper Wire Stripping Machine with Top Quality]()

Popular Motor Winding Machine Bf Scrap Electric Motor Recycling Copper Wire Stripping Machine with Top Quality

-

![PCB Crushing Recycling Machine Precious Metal Recycling Machine]()

PCB Crushing Recycling Machine Precious Metal Recycling Machine

-

![Coppler Lead Graphite Flotation Cell 0.5/0.75/1/1.5/3/8L Laboratory Flotation Separator]()

Coppler Lead Graphite Flotation Cell 0.5/0.75/1/1.5/3/8L Laboratory Flotation Separator