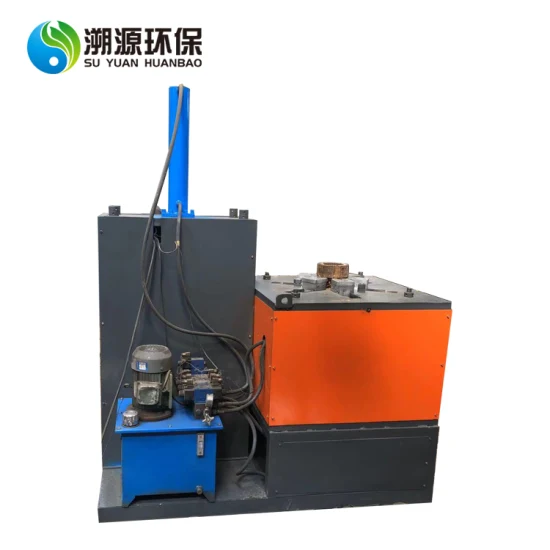

Waste Car Water Tank Copper Aluminum Recycling Machine AC Radiator Granulator Separator Scrap Copper Aluminum Recycle Machine

Description of production line Brief introduction of the production line for crushing, cleaning and granulation of soft

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | SJ120 SJ140 SJ180 SJ200 SJ240 |

| Automation | Automatic |

| Computerized | Computerized |

| Customized | Customized |

| Certification | CE, ISO9001:2008, QS, GMP |

| Condition | New |

| Other Name | Machine Plastic Pellet Recycle Granulator |

| Wast Material | Agriculture Film, Drip, Belt,Industry Film,Bags |

| Output | 200-2000kgs |

| Recycling Water | 1-2 Cbm/H |

| Reducer | 280 16:1 |

| Screw Diameter | 180mm |

| Screw Length | 2800mm |

| Electromagnetic Heating | 80+80 Kw |

| Network Switching Machine | Hydraulic Unstopping |

| Motor | 55kw |

| Feeding Motor | 2.2kw |

| Water Tank Size | 2500 X400X250mm |

| Hob Pelletizer Motor | 3kw |

| IR Supply Storage Bin | 1200 L |

| Installed Power | 3 P+1 250 Kw |

| Transport Package | Export Standard or as to Customer |

| Specification | 20000mm*5000mm*4000mm |

| Trademark | ruite |

| Origin | China |

| HS Code | 8477201000 |

| Production Capacity | 50 Sets Per Year |

Product Description

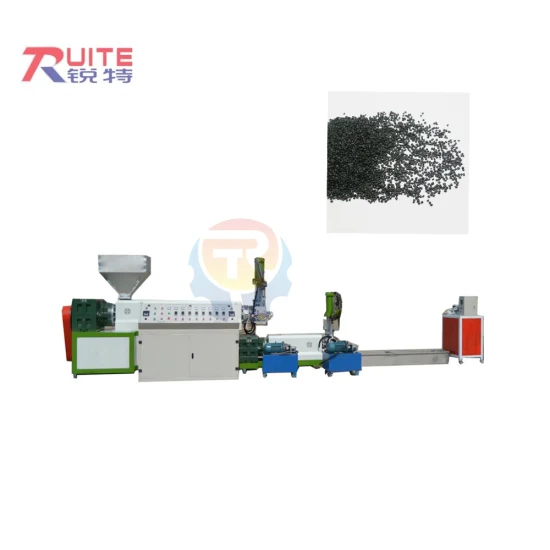

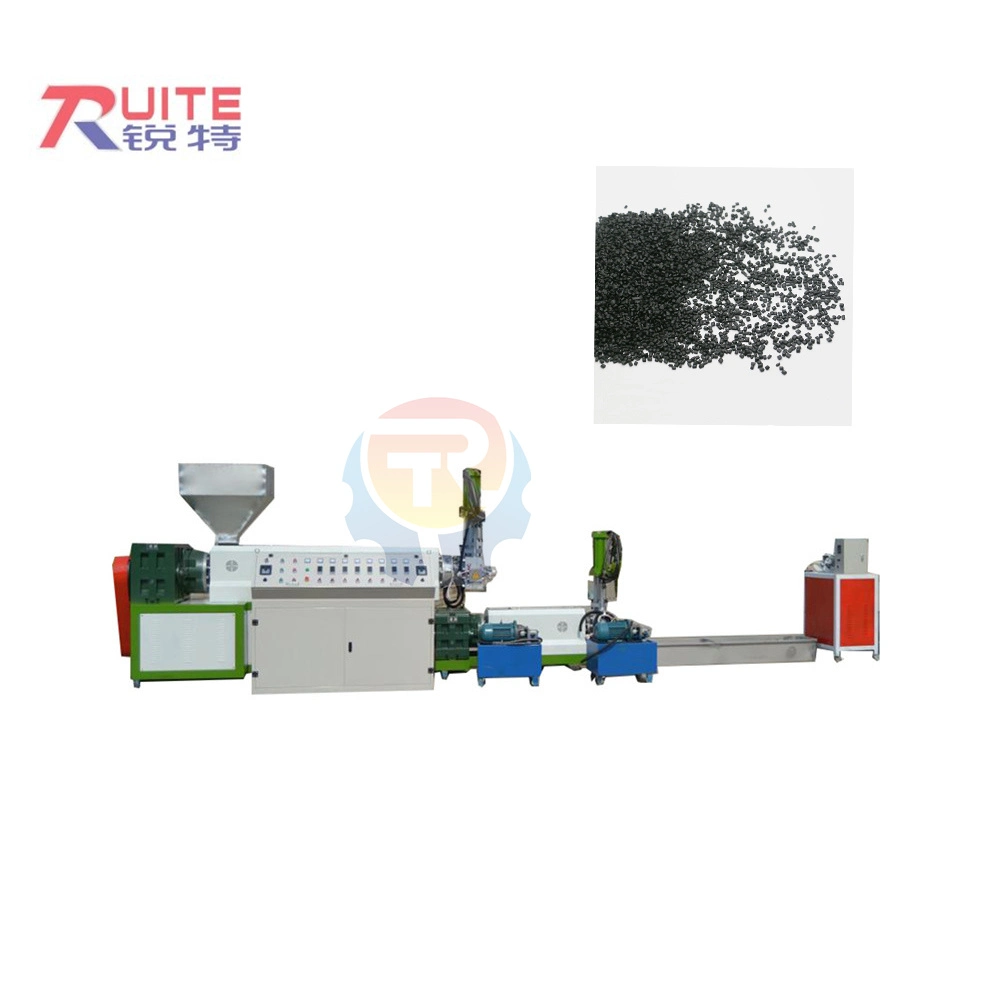

Description of production lineBrief introduction of the production line for crushing, cleaning and granulation of soft materials such as agricultural films, agricultural drip irrigation belts, agricultural water belts; LDPE, LLDPE, HDP industrial film materials, PP woven bags, ton bags and other soft materials:

This set of production line mainly deals with LDPE, LLDPE film materials such as agricultural film, greenhouse film, agricultural drip irrigation belt, agricultural water belt, industrial packaging wrapping film, PP woven bags, and ton bags for recycling and reuse.

LDPE, LLDPE film cleaning and granulation production line is a new type of high-efficiency and energy-saving advanced equipment developed by our company's research and development department after repeated tests. The features of the production line: beautiful and safe appearance, high output, low energy consumption, safety and reliability, excellent performance, and save labor costs from a great extent, this production line achieves the effect of fully automatic production.

The PE film PP woven bag crushing, cleaning and granulation production line produced by our company is the recommended product of the national environmental protection department. It complies with national environmental protection standards and has brought great economic benefits to customers in terms of environmental protection and energy saving. The pellets produced by this equipment can be reused. It is the first choice for energy saving and environmental protection and solving "white pollution".

Equipment list of production line

| NO. | Name of name | Quantity |

| 1 | ZLYJ-280 gear reducer (Changzhou Shuangli) | 1set |

| 2 | 180*2800 barrel screw | 1set |

| 3 | Electromagnetic heating 60+80 kw | 1+1set |

| 4 | 4m automatic feeder (1.5 kw) | 1set |

| 5 | Automatic feeder (2.2 kw) | 1set |

| 6 | Feeder control box (1.5 kw frequency conversion) | 1set |

| 7 | first machine hydraulic pressure does not stop to change the net die head (thickened 300/300) | 1set |

| 8 | 55 kw Motor | 1set |

| 9 | 55 kw Inverter | 1set |

| 10 | ZLYJ-225 gear reducer | 1set |

| 11 | 160*1400 barrel screw | 1set |

| 12 | Heating coil heating 10kw | 1set |

| 13 | 22 kw Motor | 1set |

| 14 | 22 kw Inverter | 1set |

| 15 | Second machine hydraulic pressure does not stop to change the net die head (thickened 300/300) | 1set |

| 16 | Cooling water tank (2500*400*250) | 1set |

| 17 | Support frame (2600*500) | 1set |

| 18 | cutter (3 kw speed regulating motor) | 1set |

| 19 | 1200L storage bin (kw 2.2) | 1set |

Machine details of each part

Main extruder

we have many different kinds of main extruder model for customer choose, depend on different output requirements. the output for soft wast film can be from 200kgs per hour upto 2000kgs per hour.

the extruder model have SJSZ120, SJSZ140,SJSZ160,SJSZ180,SJSZ200,SJSZ240 etc,

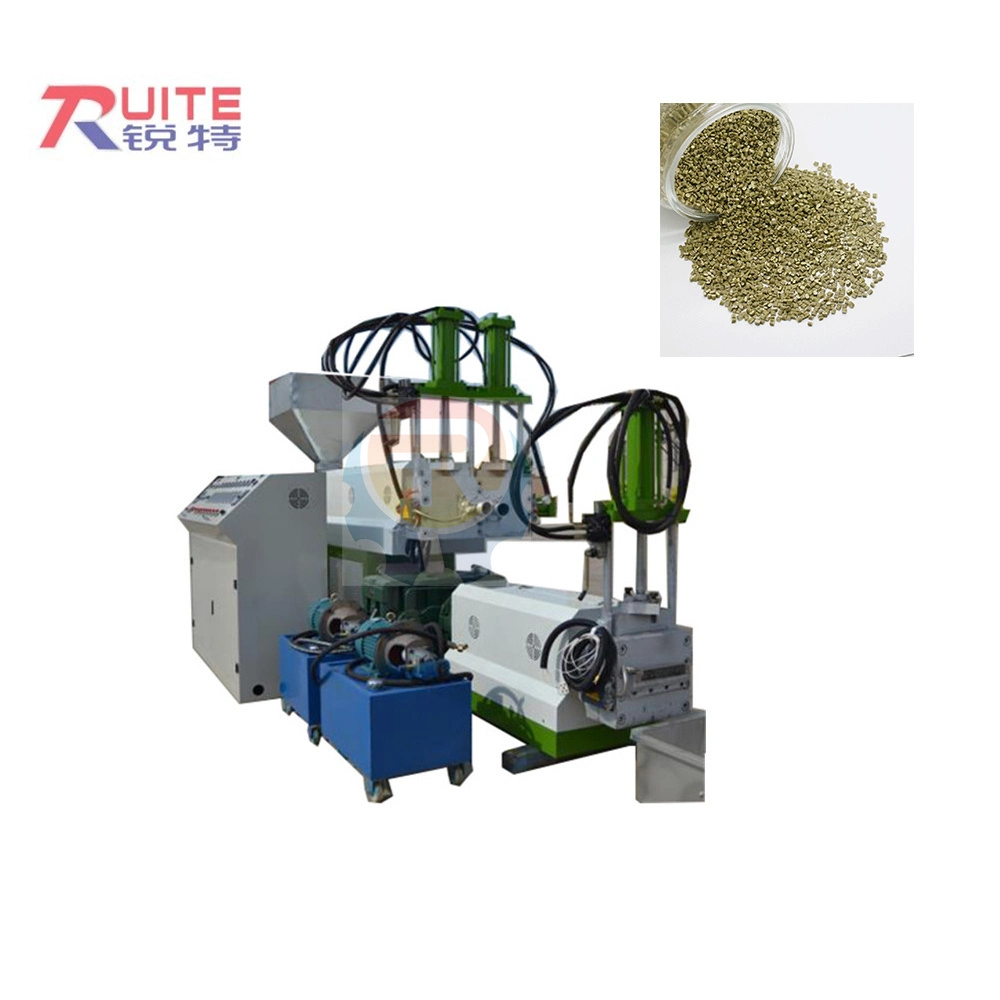

Auxiliary extruder

the model is matching with main extruder hydraulic pressure does not stop to change the net die head

- Parallel porous 27 holes

- mesh size 300*300 mm

- 4.2 mm diameter of feed hole

- Heating power 15 kw

- Hydraulic motor 4 kw

1. Tank size 2500 x400x2502. Water tank material stainless steel

Hob pelletizer(cutter)

1.Drag speed 0~35 m/min2. particle length 3 mm3. particle diameter 2-5 mm4. motor power 3 KW

Air Supply dry Storage bin

- Tank volume 1200 L

- Material material Stainless Steel

- Fan power 2.2 kw

Related products

PET-500kg/h bottle crushing and hot wash line PET-1500kg/h bottle crush and hot wash line

PP injection parts crushing, cleaning and granulation production line

Package/loading /company information

RFQ

Question: What advantages of your machine?

Answer:Quality 100% assured, famous electric brand, 24h time techincal support, Flexible payment term, Local consult office.

Question: what's the company paymet term?

Answer: 30% deposit T/T,70%balance after testing before shipment,etter of credit at sight.

Question: how long will it take to delivery after payment?

Answer: Normaly 45-50days manufacture time except some Uncontrollable factors

Question: Warranty terms of your machine?

Answer: 12 months, starting from the machine receipt in customer's warehouse

Free-of-charge of spare parts during warranty period

Question: What after sale service will offer ?

Answer: Pre-sale communication → Design proposal, signature confirmation→

Customized production→ Test machine before shipment →Package &

delivery→ Engineer installation→Training operator → Technical support

Related Products

-

![Radiator Brass Aluminum Foil Cutting Recycle Separator Machine Copper Wire Stripping Machine]()

Radiator Brass Aluminum Foil Cutting Recycle Separator Machine Copper Wire Stripping Machine

-

![Plastic Rubber Raw Material Shredding Bag Pipe Shredder Strong Force Pet PP PVC Sheet Scrap Ste Bottle Single Shaft Recycle Grinder Crusher for Injection]()

Plastic Rubber Raw Material Shredding Bag Pipe Shredder Strong Force Pet PP PVC Sheet Scrap Ste Bottle Single Shaft Recycle Grinder Crusher for Injection

-

![Waste Car Water Tank Copper Aluminum Recycling Machine AC Radiator Granulator Separator Scrap Copper Aluminum Recycle Machine]()

Waste Car Water Tank Copper Aluminum Recycling Machine AC Radiator Granulator Separator Scrap Copper Aluminum Recycle Machine

-

![Plastic Blocks Shredder/Single Shafts Shredder and Crusher Machine Unit/Plastic Crusher]()

Plastic Blocks Shredder/Single Shafts Shredder and Crusher Machine Unit/Plastic Crusher